MEAN Laboratory Capabilities

Prof. Wujcik occupies nearly 1000 sqft of laboratory and office space in Jenness Hall, housing capabilities for:

Nanomaterial and Polymer Sythesis, Handling, and Treatment

|

|

Electrospinning System (Innovenso Nanospinner 24 Multinozzle Electrospinning Machine) for producing precisely controlled electrospun nanofibers with co-axial, tri-axial, nonwoven, aligned, and a wide array of other controlled structure morphologies.

|

|

Electrospinning unit equipped with 5000 fps high speed camera (Dynamic Imaging, LLC) for real-time in-situ Taylor Cone and ejected jet monitoring. This allows for on-the-fly adjustments and overall greater control of the final fiber morphology. [Purchased with the help of a UA Alabama Water Institute Instrument Grant.]

|

|

3D (Bio)Printing (Allevi 3 Bioprinter) with three extruders, temperature control, auto-calibrated heated bed, photocuring, for 3D printing or bio-printing.

|

|

Spin coating (Chemat Tech (KW-4A) Spin Coater)

|

|

Precise Handling (A&D (GH202) Analytical Balance)

|

Heat Treatment, Synthesis, and Drying

- Across International (AT19.110) 1.9 cu ft Vacuum oven

- VWR (89511-414) Forced Air Oven

- VWR (47747-226) Explosion-Proof and Flammable Material Storage Refrigerator

- MTI (OTF-1200X-S50-2F) Mini CVD Tube Furnace

Wet-laboratory capabilities (safety equipment, hoods, glassware, stirrers, hot plates, etc.)

|

In addition to a piped DI-H2O source, the MEAN Laboratory also has an ultrapure water source (Fisher Scientific (ZRQSVP3US) EMD Millipore Direct-Q 3 UV Tap)

|

Nanomaterial and Polymer Characterization

|

Zeta Potential and Light Scattering (Zetasizer Nano ZS) for Measuring Particle and molecule size, translational diffusion, electrophoretic mobility, zeta potential of particles at high and low concentrations, viscosity and viscoelasticity of protein and polymer solutions, concentration, MW, A2, kD.

|

|

Electronic/Electrochemical characterization (CH Instrument (CHI660E) Electrochemical workstation) for electronic characterization.

|

|

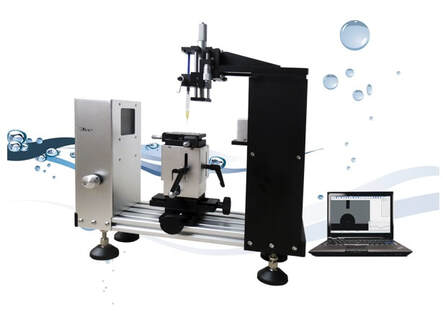

Surface Studies (USA Kino (SL150E) optical contact angle meter & interfacial tensiometer) for contact angle and surface energy studies.

|

|

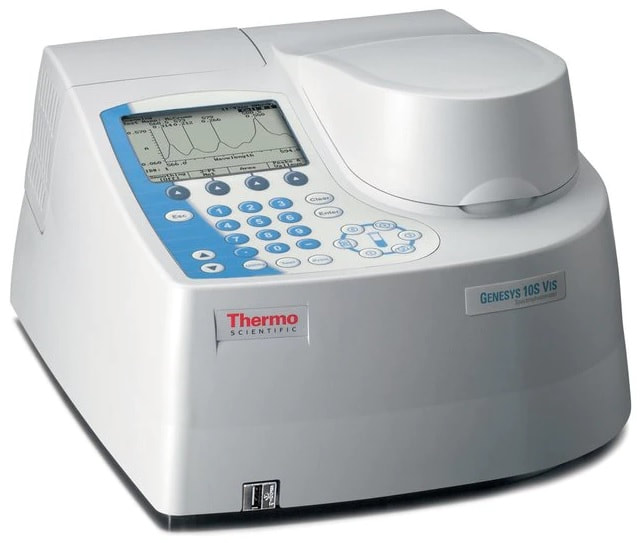

UV-Vis Spectrometer (Thermo Scientific GENESYS™ 10S) for opto-electronic characterization studies.

|

|

VWR (89231-696) Benchtop Multi-paramter Meter (pH, Conductivity, ISE)

|

Safety in the MEAN Lab

|

Safety Equipment

|

Other facilities available to MEAN Lab researchers across The University of Maine's Orono campus

UMaine's Advanced Structures and Composites Center (ASCC)As Prof. Wujcik holds a joint appointment in the ASCC, MEAN Lab members have full access to The University of Maine's Advanced Structures and Composites Center (https://composites.umaine.edu/), a world-leading, interdisciplinary center for research, education, and economic development encompassing material sciences, manufacturing, and engineering of composites and structures. The Center is housed in a 100,000 sqft ISO 17025-accredited testing laboratory with more than 260 full and part time personnel. Since 1996, the Center has:

ASCC key services or laboratories include:

|

UMaine's Frontier Institute for Research in Sensor Technologies (FIRST)MEAN Lab members also have access to The University of Maine's Frontier Institute for Research in Sensor Technologies (https://umaine.edu/first/; formerly Laboratory for Surface Science & Technology (LASST)), that has been very active in carrying out research, teaching, and outreach activities in the broad area of surfaces and interfaces, thin films, microelectronic devices, sensor technology, and nanotechnology. FIRST faculty, students, staff, and industrial collaborators profit from the synergy brought about by many areas of expertise including physics, chemistry, microbiology, electrical engineering, mechanical engineering, chemical engineering, computer science, informatics, and bioengineering. A wide variety of on-going activities span the range from fundamental research to applied development to technology transfer. FIRST has an impressive array of instrumentation to synthesize and investigate materials properties at the atomic scale and up to macroscopic dimensions, as well as to fabricate and test a variety of micro-/nano-electronic devices and micro-/nano-systems. FIRST key services or laboratories include:

|

UMaine Department of Chemistry's NMR FacilityMEAN Lab members have access to The University of Maine Department of Chemistry's NMR Facility (https://umaine.edu/chemistry/nmr/). The University of Maine Chemistry Department’s goal is to ensure the NMR Facility provides researchers with optimum NMR tools and resources. Our NMRs serve not only the Chemistry Department but also researchers from other research facilities. We encourage researchers from colleges and businesses across Maine to assess whether NMR can help them to achieve their goals. As part of this initiative, this web page provides an introduction to NMR. It also provides information and news for potential NMR users on the status of the Department’s NMRs and on how they are being utilized in various research projects. The Chemistry Department has a 400 MHz Agilent/Varian Inova NMR running VnmrJ 4.3 software 6.1 C, and a new 500 MHz Bruker Neo NMR running the latest Topspin software. The Inova has several probes including two gradient 4-nuke broadband types, a gradient indirect detection and a solid-state MAS probe. The Department also has a 45 MHz picospin desktop NMR with capillary input. Our NMRs can be run remotely from anywhere in the world using Zoom software. We use this for remote training and outreach programs. |

UMaine's Advanced Manufacturing Center [AMC]MEAN Lab members have access to The University of Maine's Advanced Manufacturing Center (https://umaine.edu/amc/) which is part of the College of Engineering. The mission of the AMC program is to link the traditional University of Maine activities of education and research with the University’s active industrial support and economic development programs. The AMC is an engineering support and service center that is dedicated to promoting economic development in Maine, and supporting the research programs at the University of Maine. The AMC is also readily accessible to businesses, entrepreneurs, and researchers throughout Maine, and North America. The AMC program is committed to maintaining a first-class facility equipped with the latest manufacturing technologies. The Advanced Manufacturing Center will design and build prototype and development projects ranging from large scale fabrications to machined parts with micro-millimeter tolerances. It has the ability to expand its range of expertise by working with engineering faculty, other UMaine research centers, and partners in private industry. Full Equipment List/Facilities can be found here: https://umaine.edu/amc/our-facilities/ |

UMaine's Process Development Center [PDC]MEAN Lab members have access to The University of Maine's Process Development Center (https://umaine.edu/pdc/) that offers its facility, equipment, and expertise for cooperative research and development projects. For over thirty years, the PDC has set the industry standard for collaborative pulp and paper research and in recent years has expanded into other technology areas, such as nanomaterials and nanocomposites. The PDC has a long track record of collaborating with partners to support traditional manufacturing as well as to create entirely new products from forest and agriculturally derived raw materials. Over the years, the PDC has served a unique role in supporting public-private partnerships, particularly within the forest products industry. The PDC offers many different testing services to support research and development projects. PDC researchers and scientists routinely analyze the properties of pulp and paper products using industry-standard test methods and environmental conditions. Custom test devices and wet lab facilities are available to serve specific needs. The PDC also performs a wide range of image analysis and microscopy, including characterizing fiber morphology and digital imaging at the nanoscale. Full Equipment List/Facilities can be found here: https://umaine.edu/pdc/facilities-available-for-use/ |

UMaine's Forest Bioproducts Research Institute [FBRI]MEAN Lab members have access to The University of Maine's Forest Bioproducts Research Institute (https://forestbioproducts.umaine.edu/). Advancing forest-based technologies and supporting our region’s forest businesses is the heart of our mission at the FBRI. Our team represents researchers from across the university who are dedicated to advancing sustainable forest bioproducts in three major categories: fuels, chemicals, and advanced materials. We seek to understand the scientific underpinnings, system behavior, and policy implications for the production and adoption of forest-based bioproducts, helping state and regional forest-based industries to harness our available forest resources in new ways. Full Equipment List/Facilities can be found here: https://forestbioproducts.umaine.edu/home/fbri-facilities-2/ |

...among others that can be found at:

https://umaine.edu/research/research-centers-institutes/

The MEAN Lab uses a variety of software to accomplish its day-to-day operation and research, inlcuding:

- Image Manipulation and Editing [free and open-source]: GIMP (https://www.gimp.org/)

- Colorimetric and Fiber Analysis [free and open-source]: ImageJ (https://imagej.nih.gov/ij/)

- Statistical Analysis and Graphing [free and open-source]: Python (https://www.python.org/)

- Citation Management [free and open-source]: Zotero (https://www.zotero.org/)